Horsham Coffee Roaster in Plummers Plain

Published on 31st January 2018

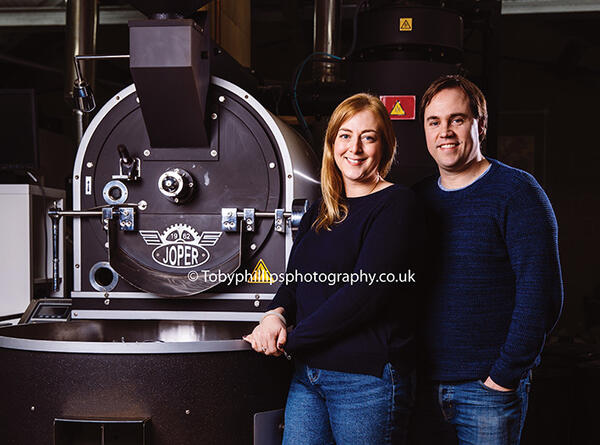

Bradley and Amelia Steenkamp, founders of Horsham Coffee Roaster, meet AAH and explain how the business grew from the garage...

1: Why Coffee?

Amelia: I was a teacher but after the birth of our first son, I didn’t want to return to a demanding full-time job. Still, I needed something to replace the income. Brad, who is a pilot, took a five-month contract in Canada and whilst there we came across lots of small coffee roasting companies. They sourced great beans and the result was that coffee generally tasted better than what we were used to back home. We thought we could do something similar as there weren’t many small batch coffee roasters in West Sussex at that time.

2: What was interesting about it?

Bradley: In Canada, traceability was important to coffee companies and customers. The coffee could all be traced back to a single farm. We are all accustomed to reading the label of a wine bottle, where the estate or region ir comes from makes a big difference to the consumer. We could see a similar trend evolving with coffee, with people caring about the product and willing to pay extra for something that not only tasted better, but was also ethically produced.

3: How did the business begin?

Amelia: We established a market stall for the Horsham Coffee Roaster in the Carfax. We’d be there every Thursday and Saturday. The roasting was all done in the garage of our home in Pease Pottage, so we were producing small amounts. We expected the bulk of our business to come from selling bags of coffee beans, but most people just wanted a nice cup of coffee, especially in the winter months. We might sell a dozen bags of coffee on a good day, but our income was small.

4: Where did you source your coffee beans from?

Bradley: There are very good businesses that have established connections with farmers and coffee producers around the world. We solely used these businesses initially, as they not only source the offee but also handle shipping and distribution. We would try various coffee from all over the world, choose those that suited us and roast them at home. Now, the business has grown to the extent that we have established our own partnerships with producers in Rwanda.

5: Why choose Rwanda?

Amelia: I set a project for pupils on Rwanda whilst still teaching. It focused on the history of the country and the genocide of the Tutsi in 1994. We felt that by sourcing coffee from Rwanda, in a small way we would be helping the country in its recovery. Bradley visited one of oursuppliers there and told me that Rwanda is beautiful and that the people are very friendly, so we made a trip together. The area around Lake Kivu is green and hilly, not at all how we imagined Africa to be. For Bradley, Rwanda is the one place that he craves going back to.

6: What was the benefit of visiting the country?

Bradley: It was great for us to see that our money was going to the right people. We’re a business and we need to make a profit, of course. But it’s a nice feeling to know that you're not cheating anyone and you’re giving the farmers a fair deal. We consider ourselves a small company, but when we went to Rwanda we were made to feel extremely welcome. We even met the mayor. They appreciate what we are doing and we could see how companies like ours make a difference to them.

7: What difference are you making?

Bradley: We visited a centralised facility where farmers bring their harvested coffee cherries and are paid upon delivery. This one facility serves about 200 farmers, so it's a cash crop for the community and we’re a part of that. We have established a relationship with a single farm, so we have full traceability. We are paying double the Fairtrade price and in some cases more, so although we’re not Fairtrade certified, we are certainly giving farmers a fair deal.

8: Did Rwanda change your business outlook?

Amelia: Very much so. We’re proud of the partnerships we have formed and want to do more to help. When we visited Rwanda last year, we visited a local school. The senior section was nice, but the primary part of the school was very old and walls were crumbling away. We decided to raise money to make it safe, so we held a few fundraising events and that improvement work was carried out during the school holidays. We would like to do more community projects in the future in various countries we source coffee from.

9: We else do you buy coffee from?

Bradley: Rwanda is the one country where we deal directly with the farmers. We have been out to Kenya and one of our team, Steve McCusker, will be visiting Costa Rica where we hope to establish new connections. We still work with reputable suppliers that provide full traceability to bring in coffee from El Salvador, Guatemala, Ethiopia, Honduras and Brazil. We hope to establish direct links in all these countries, eventually.

10: Is there a big contrast in flavour between countries?

Bradley: There's great variation in the flavour profile. Much depends on how the seeds are processed. The coffee bean is the seed inside a fruit that is often referred to as a cherry. After picking, some producers run the cherries through a wet processer, which strips off the fruit and leaves the coffee bean, which then go through a fermenting process. Other farms adopt a more traditional method, picking cherries straight from the tree and removing the fruit by hand. This method usually results in a fruitier coffee bean. Both methods have their advantages and disadvantages.

11: Which style do you prefer?

Amelia: We lean towards traditional methods as we like the fruity tones. It also tends to be more beneficial to the community as it supports more workers. In Rwanda, we have asked for our farm to provide us with micro lots of coffee, using various harvesting methods. Like wine, the way the cherries are harvested can affect the flavour. For these micro lots, we pay an additional $2 per kilo, so there is great incentive for them when they’re producing 1000kg for more money and no additional cherries. It helps them increase their profits, which benefits the entire community.

12: What do you do with the coffee beans?

Bradley: Our job is to properly roast the beans and prepare them for sale. Much like the harvesting process, the roasting process is hugely important. If you remove beans from the roaster too soon, the coffee will taste weak and grassy, which is immediately recognisable to customers. Leave the beans in the roaster too long and you end up with a burnt and bitter taste. There are natural sugars in coffee, because it's an organic product. The sugars start to caramelise and produce a fruit flavour whilst roasting. You need to go beyond the caramelisation stage, yet maintain sweetness, so it’s a balancing act.

13: What kind of roasting machine do you have?

Bradley: Our roaster is made by Joper, a family-run firm in Portugal. I went to visit the company and liked the way they build their machines. They’re very solid and look like old steam trains. Cast iron is a good material for the roasting process. This machine also has good software control, integrated into what looks like a vintage piece of kit. We are very specific as to how we roast and we use the software to maintain consistency. We measure time,temperature, intensity of heat and airflow throughout the process.

14: How many finished coffees do you have?

Bradley: Most of what we offer is single origin coffee, such as Rancho Alegre from Nicaragua, Kianderi AA from Kenya and Suke Quto from Ethiopia. They are labelled with traceability to one producer. We also have two blends that combine coffee beans to create a certain flavour. The two Horsham Coffee Roaster blends are Workhorse and Pioneer. Pioneer is fruity and sweet, whilst Workhorse is more traditional, with a nut and chocolate aroma. We also make bespoke blends for customers.

15: Who are these customers?

Amelia: One of our customers is The Flying Coffee Bean, which has many outlets at railway stations. They have been a good customer, and now their business has grown to the extent that they will be roasting their own coffee. We’re in the fortunate position of supplying lots of companies, so we don’t have all our eggs in one basket. People can also buy our coffee bags from farm shops including Crates in the Carfax and Plaw Hatch in Sharpthorne.

16: Do you still sell at the Carfax market?

Amelia: I stopped doing the market after the birth of our second child. It became very difficult to continue with a baby around. Although people would help me, it wasn’t manageable. I do miss being part of the market and chatting to the public about coffee, but at the time, the wholesale side of the business was growing and where we were expanding. We moved out of the garage, which was great for me personally as the whole house was starting to smell of coffee!

17: Where did you move to?

Amelia: We rented a unit on Church Lane Industrial Estate in Lower Beeding, working with a 15kg coffee roasting machine. Two and a half years ago, we moved around the corner to where we are now, The Studio at Howards Nursery, Plummers Plain. We had bought the Joper roaster, which wouldn't have fit through the door of our previous unit. We purchased the roaster thanks to a Sussex business scheme grant.

18: Can people just drop in to The Studio for a coffee?

Amelia: We have created a bar area so that people can drop by. Some customers like to buy some bags of coffee too. We use Stephen’s beautiful espresso machine, although he is hoping to open his own coffee shop in London soon and he’ll be taking that with him. We don’t have too many people coming in, as we’re a bit out of the way, but we have regulars.

19: Is the coffee expensive?

Bradley: The producers work very hard to produce an organic product and the price needs to reflect that. As well as being a quality product, we need to ensure that all the relevant information is communicated to the end user as that makes a lot of difference to the conscientious coffee drinker.

20: Have I missed anything?

Bradley: I didn’t mention that I’m a licensed Arabica Q Grader. It’s a high-level coffee qualification based around a set gradingsystem for coffee. This reinforces the standards of specialty coffee and demonstrates integrity within the supply chain.

WORDS: BEN MORRIS

PICTURES: TOBY PHILLIPS

Visit Horsham Coffee Roaster at The Studio, Howards Nursery, Handcross Road, Plummers Plain, RH13 6NX or online at www.horshamcoffeeroaster.co.uk