Ceres Power in Horsham

It may not look that exciting, but a unique fuel cell developed by Ceres Power could play an important role in the fight against climate change.

Based at Viking House in Foundry Lane, Ceres are pioneers of unique technology that can be used to provide clean energy for homes, businesses and modes of transport, helping to accelerate a global transition from combustion technologies towards zero carbon, affordable energy.

With the world’s interest in fuel cell technology expected to grow, the value of Ceres Power has soared since it first floated on the London Stock Exchange (LSE) in 2005. While continued investment has helped fund development, the high share price also brings added pressure from the City. However, Ceres has maintained the feel of a local business and only last month received the Queen’s Awards for Enterprise.

Michelle Traynor, Director of People at Ceres, says: “I live in Horsham and find working for a company tackling climate change hugely rewarding. Environmental issues that we face today are not going away and we are playing an important role in helping to preserve the planet for future generations.”

EARLY DAYS

Ceres Power was founded in 2001, borne out of Imperial College London and initially based in Exhibition Road, Crawley. The business was headed by fuel cell pioneer, Professor Brian Steele. His idea was to make a fuel cell that could generate power from conventional fuels (like natural gas) and sustainable fuels (biogas, ethanol or hydrogen) using a cost-effective steel base. It is this unique concept that Ceres has spent 20 years perfecting.

Carl Matthews, Cell Manufacturing Engineering Lead at Ceres Power, has worked for the company for 17 years and recalls its early days. “There were only 20 people when I first joined. It was a heady mix of talent, most of whom had PhDs. I wasn’t one of them, but I felt a strong connection with what Ceres was trying to achieve and realised it was a once-in-a-lifetime opportunity.”

“I joined in January 2004, three months after Brian passed away. So, I never met him, but acolytes and academics who worked alongside him continued his work and we’ve been on that journey ever since.”

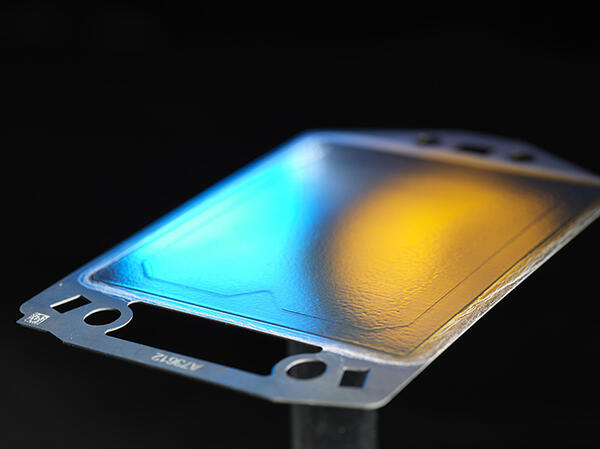

Brian’s idea led to the development of the patented SteelCell (above and left). Most fuel cells use platinum as a base material, because it’s an ideal catalyst for the electrochemical reaction that separates hydrogen into protons and electrons. However, platinum is a rare and expensive metal, and one of the reasons why fuel cells haven’t been considered a financially-viable option for green energy in a world reliant on abundant, cheap fossil fuels. But Brian believed he could use a cheaper material and still make it efficient. “For many years, Brian thought he could make fuel cells on a steel base,” says Carl.

“People in the fuel cell industry said it couldn’t be done, as steel can’t cope with the temperatures involved. But by gaining a deeper understanding of the ceramic compounds and material characteristics, Brian achieved what others had deemed impossible.”

THE STEEL CELL

Core to the technology is how to use a widely used material - ferritic steel - as a backbone on which a ceramic electrolyte could be printed, reducing the cost, the use of rare earths and the complexity of manufacturing. In Ceres’ case the ceramic electrolyte is cerium, inspiring the name of the company.

One fuel cell alone only generates enough to power a low energy lightbulb. But stack them together and 100 fuel cells might power a home, while even bigger stacks could power a car, business or even a block of flats.

Generating more power from each cells is a key focus for the engineers. Carl says, “I call the Horsham site the “Brains Trust” and our of its roles is to generate more power from a single cell. The more energy you generate from a cell the better, as it’s all about lowering the cost, in terms of dollars per kilowatt, and making affordable and efficient energy.”

“In my time here, advances in fuel cell power has been huge. The Apollo space missions used fuel cells, so the technology is nothing new, but the evolution has been in power density, with less architecture and lower costs.

“In simple terms, a fuel cell is a single-sided 2-dimensional device. It hasn’t changed much in terms of its basic chemistry, but the innovation has been what happens around it. Over the course of 20 years, it’s been a matter of evolution rather than revolution. The next revolution for us is in generating hydrogen.”

REVERSE A FUEL CELL

A promising new application for Ceres' solid oxide technology is in the development of solid oxide electrolysis (SOEC). Essentially, this reverses the operation of fuel cells to produce hydrogen from electricity, which can produce green hydrogen when using renewable energy.

The cleanest energy source (in terms of its natural abundance, anyway) is hydrogen, as its only by-product is distilled water. However, hydrogen cannot be found naturally in a pure state, so therefore needs to be produced in other ways. One way is electrolysis, which separates the molecule H2O into oxygen and hydrogen.

Not everyone is convinced by the hydrogen economy though. Tesla CEO Elon Musk, has labelled fuel cell cars “mindbogglingly stupid.”

“In the automotive world, people are hedging their bets on different outcomes,” says Carl. “Companies like Tesla back pure EV (plug-in electric vehicles) which essentially are battery-powered, while others are developing fuel cell technology, with Toyota being a trailblazer. Then you have those investing in a hybrid of the two. It’s fair to say that not one will dominate and they’ll eventually be complementary.”

As for Ceres’ technology, SOEC is the most efficient class of electrolyser technology, with the potential to produce clean hydrogen at greater than 90% efficiency when coupled with waste heat and steam. It is not targeting car refuelling, instead focusing on industrial processes, like steel and ammonia production. Early testing on the application of the technology in SOEC has delivered encouraging results.

CHANGING DIRECTION

That may be the future, but in the present, Ceres Power is expanding with a new approach that sees it working on innovative ideas with global partners.Phil Caldwell was appointed Chief Executive in 2013. Under his leadership Ceres has grown into a world-class clean energy technology business, and the switch in focus is bearing fruit.

Carl says: “Previously, we had been looking at our products and thinking ‘how do we turn this into a boiler to power a home?’ We wanted to control the whole process to protect our trade secrets. Now, we work with businesses who have their own ideas but need our knowledge and expertise to realise the potential of the technology. Our whole business model has changed.”

“Our value is now taken from our innovation. I don’t even view us as a fuel cell company anymore. We’re currently about solving problems relating to energy generation. Phil has been instrumental in establishing partnerships with global engineering and technology players such as Bosch in Germany, Weichai in China and Doosan in South Korea, to meet the urgency for low carbon power systems in industry, data centres, transportation and everyday living.”

Bosch recently announced £1billion of investment in fuel cell development and has acquired a stake in Ceres Power too. One of its key aims is to make Cloud storage data centres environmentally friendly.

“There’s increasing demand on data servers and they consume power at an unbelievable rate,” said Carl. “The architecture of running these servers requires high consumption of energy, but you also need to keep them cool, which uses up even more power. Bosch are working on the development of new data servers which are more efficient because of fuel cell technology.” “There is endless potential for us to grow, from powering residential properties to major businesses and transport. We are exploring revenues in the marine sector, as ships are not “clean” ways of transporting goods. There are fuel cell companies exploring aviation uses too, to create greener travel. We’re also seeing the emergence of e-fuels, which will influence every sector of the energy industry in future. The sky’s the limit!”

“During my time here, I’ve seen huge change. There have been ups and downs, particularly the tough market conditions of 2008, and a lot of restructuring along the way. From a small team, we have grown to a company with over 300 employees, with a second site near Redhill in addition to this one in Horsham. However, it still feels like family. A highly intelligent and at times quite a challenging family, but a family nonetheless! I can still walk into the CEO’s office or pop down and chat to the engineers on the shop floor. I’ve no doubt we can maintain that feel as we move forward.”

Words: Ben Morris

For videos on technology and job opportunities, visit https://www.ceres.tech

(Published on 1st June 2021)